Flex-fuel vehicles (FFVs) that run on any combination of ethanol and gasoline have been around for decades. Depending on your geographic location, E85 fuel may not be readily available. As a result, you may have not seen an ethanol-related drivability issue. However, when one does come into your shop, and it will, you will need to be prepared to deal with it. Too many technicians feel this may not seem like a concern. I hear things like, "There are no gas stations with E85 in my area" or "Customers with flex-fuel vehicles only run gasoline." Both of these statements may be true to an extent. Allow me to elaborate.

There are areas of the country where E85 is available. One of the most common areas to find E85 is along major highways. Watch the next time you go on a road trip and see if E85 is available. Now think about it for a minute: a tank of fuel can get you about 300 miles on average. What if one of your customers filled their tank while on a journey? Could a customer have accidentally filled their tank with the wrong fuel 200 miles from your shop? It happens! My first experience with E85 was almost two decades ago. A customer brought a 1998 Chevy T10 Blazer with a 4.3-liter engine into the shop for a MIL illumination complaint. This vehicle was a non-FFV (only designed to run on conventional gasoline) that had lean DTCs stored and no obvious performance issues. My diagnosis took some time, I learned as I went, and I determined that there was ethanol in the tank. About 54 percent ethanol according to my test. Since then, my techniques have been corrected and honed.

What I want to address today can be broken into two parts: non-flex-fuel vehicles with ethanol in their fuel tank and flex-fuel vehicles that have learned ethanol content incorrectly. In both cases, our goal is to have a quick indicator of the potential issue and an easy way to confirm the situation. Before we can address these two possibilities, we need to cover some theory first.

Oxygen sensors, A/F sensors, and fuel trim

First, oxygen sensors do not "measure" oxygen. Air fuel ratio sensors behave similarly. Both of these types of sensors (when working correctly) report Lambda. Lambda is a value that represents stoichiometry. We are probably all familiar with the stoichiometric air to fuel ratio of 14.7 to 1. This is the stoichiometric ratio for gasoline. The stoichiometric air to fuel ratio for ethanol is closer to 10 to 1. The sensors in question, report lambda (or stoichiometry) to the PCM, regardless of the fuel type. For now, let us avoid the chemistry, physics, and engineering details of these sensors.

Second, fuel trim numbers are based on the previously mentioned sensor inputs. Total fuel trim (short term + long term) will be our key to diagnosing ethanol-related issues. To be fair, fuel trims are extremely valuable when diagnosing a myriad of issues. Using fuel trims for effective diagnosis involves operating the vehicle under different conditions. For example, a vehicle with a vacuum leak will present with high positive total fuel trim under idle conditions and be closer to normal at higher RPMs. Conversely, a restricted fuel filter might result in normal fuel trims at idle but have high positive total fuel trim numbers under load. Different fuel types behave differently. Because the fuel “TYPE” is different, total fuel trim numbers will be skewed equally, either high or low, under all driving conditions.

FFV ethanol in the fuel tank

When a non-FFV is accidentally filled with E85 it usually exhibits complaints such as MIL illumination, lean DTC's, low power, and even crank-no-start. If the vehicle starts and runs, the previously mentioned fuel trims will point us in a direction quickly.

I was recently called to diagnose a 2016 Subaru Forester that had been in and out of a shop. The original complaint was of MIL illumination for P0171 – Lean Exhaust Bank 1. The spark plugs, air filter, and fuel filter had already been replaced. A "Fuel System Service" had also been performed which I believe meant some type of injector flush. The DTC's were cleared and the vehicle was returned to the customer. A week later the vehicle returned with the same lean DTC and the shop was leaning towards an A/F sensor issue. Time to start from scratch.

The vehicle still had a P0171 so the DTCs were cleared after gathering and recording baseline data. A fuel trim reset was performed, and the car was taken on a test drive. Scan data was recorded and can be seen here (Figure 1). For reference, the top trace is engine RPM. This PID allows you to see that the vehicle was driven under multiple conditions. Please note that after the fuel trims were cleared the engine would start and stall as it did in the first few moments of the capture. Opening the throttle slightly and “playing” with the throttle angle got the vehicle running. This is another good indicator of a potential air/fuel related issue. The next three PIDs in order from top to bottom are as follows: Loop status, short-term fuel trim, and long-term fuel trim.

I know it is hard to see in the scan data because you cannot move the cursor around but allow me to share what I gleaned from the recording. I measured total fuel trim (STFT+LTFT) at multiple places in the capture. The highest number I observed was positive 39.3 percent and the lowest number I found was positive 32.8 percent. If we look at deviation (highest minus the lowest) our window of operation is only a 6.5 percent under all conditions. If we stick with the rule of thumb that seems to be popular in the industry, plus or minus 5 percent are good fuel trim numbers. That equates to a 10 percent window. Although the trims on this Subaru are high under all conditions, they are definitely within a 10% window no matter how the car is being driven. This is a good indicator of ethanol in the fuel tank or potentially other "fuel-type” issues.

The next step was to take a fuel sample and test for the ethanol content. In this case, the ethanol content was around 73 percent. That is not going to sit well with a vehicle not designed for E85. How I perform an actual ethanol test on a fuel sample will be covered later in this article.

FFVs that have learned ethanol content incorrectly

On the other side of the coin, we can have FFV’s that have accidentally learned their ethanol content incorrectly. The fuel trim numbers will be our key to diagnosis in these cases as well. FFVs usually have an ethanol PID (or something with a similar name) in the data list. If this number is high the tank could have ethanol in it… or maybe not. If the learned alcohol value is higher than what is actually in the tank the PCM ends up confused. What usually happens, in this case, is the vehicle stores rich DTCs.

The next vehicle in question is a 2011 Ford F-150 with a 5.0-liter engine. It has a P0172-Rich Exhaust Bank 1 and a P0175-Rich Exhaust Bank 2 stored. The freeze frame data was retrieved and both banks of the engine have extremely negative fuel-trim numbers (Figure 2).

Just like the Subaru, it is time to test drive the vehicle under multiple operating conditions and observe the fuel-trim numbers to choose our diagnostic path. Because this is an FFV, the ethanol PID will also be checked. In this case the FF_INF (Flex Fuel Inferred) PID is at 77.64 percent. The test drive also confirms that the fuel-trims are negative under all conditions (Figure 3). If we do the math as we did for the Subaru, Ford's fuel-trim numbers also fall within a 10 percent window. These numbers indicate a fuel related issue but in the opposite direction.

The next step was to take a fuel sample and test for the ethanol content. The fuel in the tank of this F-150 tested to be approximately 7 percent ethanol which is a very common percentage to come out of the ground of a non-E85 gas pump.

Now we have a dilemma: How do we relearn the correct ethanol content? On this particular vehicle, there is no option for an ethanol reset in the scan tool. The DTCs were cleared and the FF_INF number remained. A KAM (Keep Alive Memory) reset was performed with no success. At this point, we only have two options that I am aware of. First, we could pump most of the fuel out of the tank and drive the vehicle. Then we turn the vehicle off, refill the tank and drive the truck to force the relearn to occur. This option is not high on my list.

Second, we could trick the PCM. Since the PCM uses the fuel level sensor to determine if there has been a fueling event between key cycles, we can use that strategy to our advantage. Instead of draining the fuel tank, install a resistor of an appropriate value to make the fuel gauge read low, drive the vehicle for a short period, turn the key off, remove the resistor and drive the vehicle again. This will trick the vehicle into thinking it just had a fueling event and should force the inferred ethanol to learn to take place.

Some vehicles allow ethanol reset with the scan tool which makes the fix much easier. The scan data shown is from a 2011 Chevy Silverado with a 4.8-liter engine (Figure 4). It exhibited the same DTCs identical fuel-trim behavior to the previous F-150.

On this vehicle the “Fuel Alcohol Content” PID read 76%. An ethanol test was performed on a fuel sample and the result of approximately 4% was obtained. This particular application allowed “Fuel Composition Reset” in the “Special Functions” menu of the scan tool. After the reset was performed the vehicle was driven. The “Fuel Alcohol Content” PID adjusted to 3%, fuel-trim numbers were now normal and the rich DTCs did not return.

Testing for ethanol

There are a few ways that we can test a fuel sample for the ethanol content. One way is to acquire a fuel composition tester such as the J-14475. Another way, and a more cost-effective one, is to use an empty bottle or a graduated cylinder. I prefer the latter because it will yield an approximate ethanol percentage as opposed to a pass/fail result.

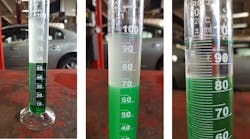

We all are likely aware that gasoline and water do not mix. However, ethanol and water do. Using this fact to our advantage, mix 50 milliliters of a fuel sample with 50 milliliters of water. The dividing line of the two liquids should be easily visible. To make things a little easier to see I sometimes use a couple of drops of food coloring which also will not mix with the gasoline. Shake the sample carefully and let it sit for a moment to allow the two liquids to separate again.

Observe where the dividing line of the two liquids settles. The dividing line would be at 50 milliliters if the sample was 100 percent gasoline and 0 percent ethanol. If the line rises, say to 55 milliliters, that is an increase of 5 milliliters. Multiply that increase by 2 (5 x 2 = 10) and that is our approximate ethanol percentage (10 percent). No hardcore chemistry lab is required.

Here is the result of three ethanol tests (Figure 5). The first sample yielded a 7-milliliter increase which indicates an ethanol content of approximately 14 percent. The second sample rose 20 milliliters which indicate 40 percent ethanol. The last sample settled 35 milliliters higher than our starting point which equates to 70 percent ethanol.

This test is easy, quick, and very useful for identifying ethanol in the tank of a non-FFV. It is also useful for checking to see if an FFV's ethanol content PID matches what is actually in the fuel tank.

An additional note

Please be aware that the fuel trim technique covered above can be used to find faults other than ethanol miscalculations. What I am referring to is even less common than ethanol issues (but can still happen). In most cases, the other issue that comes to mind is usually man-made and pertains to injector fuel flow rates.

If an engine is replaced with a used unit, there is a possibility that the fuel injectors on the used engine have a different flow rate than the original fuel injectors. If this occurs, all of the cylinders will receive either too much, or too little fuel (under all conditions) if the injectors are operated with the original vehicle’s injector pulse-width. These situations usually present with either rich or lean DTC’s and do not usually have any other drivability concern. Again, the equally skewed fuel trim numbers under all conditions are the key to finding this quickly. After performing an ethanol test to rule that possibility out, the next step would be to start investigating the injectors. On the same note, if all of the injectors are replaced on a vehicle that has the wrong flow rate the result, and diagnostic technique would remain the same.

I do not mean to point fingers at technicians when this happens. Remember we are all human and mistakes happen. The same statement applies to customers who accidentally fill their fuel tank with E85 (Accidents happen). Either way, a basic understanding of what to watch for, how to perform a few simple tests, and a sound logical process will lead you quickly down the road to making an accurate diagnosis.