Summer can bring extreme conditions that really take a toll on vehicles. Now is the time to start planning preventive maintenance (PM) that will keep your fleet on the road and keep your business in the black.

So advise officials with Gates Corporation (http://www.gates.com), a global diversified manufacturer of industrial, automotive and heavy duty aftermarket products. Prepare for the season “by practicing a system-centered approach to inspection and repair.”

Worn components can put the entire serpentine, timing and cooling systems at risk, they note. Since all of the parts in a system are engineered to work in concert and wear at about the same rate, inspect and repair the full system instead of just a single part.

Share the following best practices with your technicians to help prepare your fleet for the heat.

SERPENTINE SYSTEM

Check all components of the serpentine belt system, including the belt, tensioner, idler pulley and alternator decoupler pulley, say Gates officials.

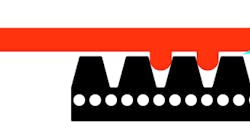

Most of the belts on today’s commercial vehicles are made of EPDM (ethylene propylene diene monomer) material, which lasts much longer than older belts that used chlorinated rubber (Neoprene) in their construction, they point out. However, EPDM belts don’t necessarily exhibit traditional signs of wear, so a simple visual inspection is often not sufficient to determine if a belt is at or near failure.

A belt is much like a tire in that as the tire rotates and comes into contact with the ground, it wears. A belt wears in much the same way. It comes into contact with pulleys as it moves around the drive system.

Over time, the grooves cut into the belt, gradually wearing it away, explain Gates officials. This material loss results in poor performance, such as reduced wedging force between the belt and pulley. This can lead to belt slip, which causes severe vibration and a reduced ability to transmit power, often leading to inconsistent alternator performance or poor A/C system performance.

An effective way to check for belt wear is to use Gates’ new Belt Wear Gauge. (It can be obtained for free by visiting the company’s website.) This tool provides a simple and reliable way to determine if a serpentine belt has lost enough material to negatively affect performance and warrant replacement. It is easy to use one-handed, even in hard-to-see places, and gives instant pass/fail results.

The tensioner maintains consistent tension on the belt and is an integral part of the belt drive system, they say. A loss of tension can create belt slip and heat, leading to premature belt failure. A faulty tensioner will reduce the wear life of the belt and affect overall engine performance.

For a complete system repair, they recommend inspecting and replacing the tensioner and belt at the same time if needed. Also, check that the idler pulleys smoothly connect the belt to the system. Worn pulleys can misalign and cause system damage.

TIMING SYSTEM

Gates officials advise checking all components of the timing system, including the timing belt, water pump, idler pulley and belt tensioner.

- The timing belt synchronizes the engine to ensure smooth operation. Belt failure will cause an immediate breakdown and can ruin engines.

- The water pump pumps coolant through the engine, radiator and heater core. Failure can cause engine overheating and breakdown.

- Idler pulleys smoothly route the belt around the engine. Pulley inspection is important as even a worn bearing could lead to belt and system failure.

- The belt tensioner maintains proper tension on the belt system. Ninety percent of timing belt failure is attributed to tensioner or pulley failure.

COOLING SYSTEM

All cooling system components – including the radiator, thermostat, water pump, radiator hoses and clamps – need to be checked as well, add Gates officials.

- The radiator removes heat from coolant fluid. Radiator damage, improper coolant mix or blockage can diminish the system’s ability to cool the engine.

- The thermostat regulates the temperature within the system. Malfunctions can cause engine overheating and breakdown.

- The water pump pumps coolant through the engine, radiator and heater core. Failure can cause rapid overheating which could critically damage the engine.

- Radiator hoses transfer engine coolant to and from the radiator. Hoses wear from the inside out and can be difficult to visually inspect. If other critical cooling system components are being replaced, it makes sense to replace both upper and lower hoses together to ensure a complete repair.

“Be system smart and keep your fleet on the move and out of the shop this summer season,” sum up the officials. “Protect vehicles from inconvenient breakdowns and expensive repairs by fully maintaining the critical serpentine, timing and cooling systems.”