How often does service information misdiagnose an electrical concern? How many times have you performed every procedure and replaced what it said to replace, only to still not repair the concern?

Not all service information has errors, but I have noticed that it assumes a lot and expects technicians to do testing without a full explanation of why the test is being performed. Many test procedures are static, meaning when the vehicle is stationary and no electrical load on the circuit, versus dynamic.The problem with static testing is that most of the time it will show good/within parameters. Once tested in a dynamic state, it will fail. Dynamic testing is a much better way of diagnostic testing because the vehicle is in the normal state of operation during the test, and more likely to show the failure.

I provide electrical training all over the world, and I’ve noticed most technicians, if shown an easier way of doing things, they will do it. However, on more detailed testing that requires some critical thinking, they shy away from analyzing test data. I also feel that technicians rely on scan tools way too much and base a lot of circuit analysis on scan tool data. That can really take you down a path of frustration and misdiagnosis.

Advanced electrical diagnosing

Why am I telling you all of this? I have recently been training technicians on advanced electrical diagnosing using an oscilloscope, and from time to time, I get comments like:

“I never needed a scope before, why now?”

“I can do everything with my DMM (digital multimeter).”

“I can do everything I need with the scan tool.”

“It takes too long to set up.”

“Service information never asks me to use a scope.”

“That's old technology...”

“That is snake oil.”

Most technicians I train are excellent technicians and embrace anything that will allow them to diagnose faster and more accurately. But, from time to time, I get the comments above. I completely understand why these comments come up, so I just want to follow up and give my perspective on some concerns of mine and misconceptions about oscilloscope diagnosis.

Some of those misconceptions include:

- The oscilloscope is only used for complex electrical concerns.

Can you diagnose complex electrical concerns with an oscilloscope? Yes, and it is most likely the only tool fast enough to perform the more advanced concerns.

- Wait until you have exhausted all testing. Then, and only then, use the oscilloscope. Can I diagnose mechanical concerns much faster than conventional methods? Yes, and when used properly, you can look at many mechanical concerns in a fraction of the time. How many times have you disassembled something and see that is okay, only to have to put it all back together and start your diagnose all over?

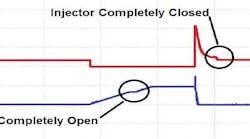

- The oscilloscope is extremely difficult to use and to understand the waveforms. Can you diagnose simple circuits and see things that you could never see before? Yes, you can look at electrical and mechanical concerns that your scan tool and DVOM just couldn't do.

Review the number of oscilloscope waveforms here for examples that disprove these misconceptions.

Relatable industries

Looking at the waveforms and patterns, where have we seen something like this in another profession? The medial field - in an ambulance, first responders, paramedics, doctors and cardiologists. These folks use an oscilloscope to understand what is going on inside a patient clearly, in real-time.

Medical professionals check blood pressure, pulse rate and other vitals with this technology, just measured much slower than the speed of information moving through our trucks. The only real difference is the speed in which the scope is designed to accurately measure the real-time information needed to make diagnostic decisions.

In closing, if technicians diagnose electrical, mechanical and communication concerns on vehicles in today's service industry, make sure they have all the tools and proper training their toolbox.

Be sure to see the whole picture with an oscilloscope to start diagnosing vehicle issues more quickly and more accurately.

Keith E. Littleton is president of K&D Technical Innovations, a service provider offering training solutions for industry and education. Littleton specializes in CAN communication issues and lab scope diagnostics, and is the current Station Chair for TMC SuperTech’s electrical test station. Littleton holds numerous ASE certifications, as well as nine Toyota certifications and 11 GM certifications.